APPLICATION PROCEDURES

- Follow the instructions described from point 1) to point 4) of the RINFOR SYSTEM 1 ;

- Remove the existing plaster on the masonry close to the beam (or the floor), for a width of 10 cm;

- Dust the carving surface and wash it with low pressure water;

- Complete the intervention by incorporating and covering the ARMAGLASS STRUCTURA 250 mesh with a centimeter layer of UNISAN* composite mortar, fiber-reinforced with double type of READYMESH fibers (glass and polypropylene), dehumidifying, very high breathability, class R (restoration according to UNI EN 998/1), based on hydraulic binders with a low content of soluble salts, with mechanical resistance in class R2 (according to UNI EN 1504/3), reaction to fire class A1 (EN 13501-1), permeability to water vapor 11 μ (UNI EN 1015-19), compressive strength after 28 days > 20 N/mm² (UNI EN 12190), flexural strength after 28 days > 5MPa (UNI EN 12190), elastic modulus 11 GPa (EN 13412), maximum particle size of the aggregate 1.5 mm; mix the mortar with water according to the proportions indicated in the technical data sheet, continuing the mixing for at least three minutes and in any case until a homogeneous, creamy and lump-free mixture is obtained; laying the mortar manually or by spraying (with a suitable sprayer for fiber-reinforced mortars), taking care to perfectly cover the surface of the substrate, without gaps or shaded areas; thickness of the mortar from 1 to 2 cm approximately. Consumption of about 15 kg/m²/cm thickness;

- Regularize the surface of the mortar avoiding excessive smoothing to leave the surface slightly rough with sufficient grip for the subsequent skim coat; wait for the mortar to cure properly before proceeding with skim coat;

f. two-coat smoothing performed with SANASTOF premix of mineral composition, based on natural hydraulic lime NHL 3.5, microsilica with pozzolanic activity, selected aggregates, high tenacity microfibers, light heat-insulating aggregates with low modulus of elasticity; consumption of about 3 kg/m² for two applied coats and a total thickness of 2-3 mm; - Finish the surgery with a highly breathable colored finish using products from the SANAXIL or PROTECH SIL line

* as an alternative to UNISAN mortar, the super adhesive RASOCOAT mortar can be used, based on hydraulic binders, water-dispersible resins, silico/limestone aggregates and specific agents. Main technical characteristics of RASOCOAT mortar: Adhesion bond (UNI EN 1015-12): > 1.5 N / mm²_ Density: 1.90 kg / l _ Compressive strength after 28 days (UNI EN 1015-11): > 20 N / mm² _ Flexural strength after 28 days (UNI EN 1015-11): > 6 MPa

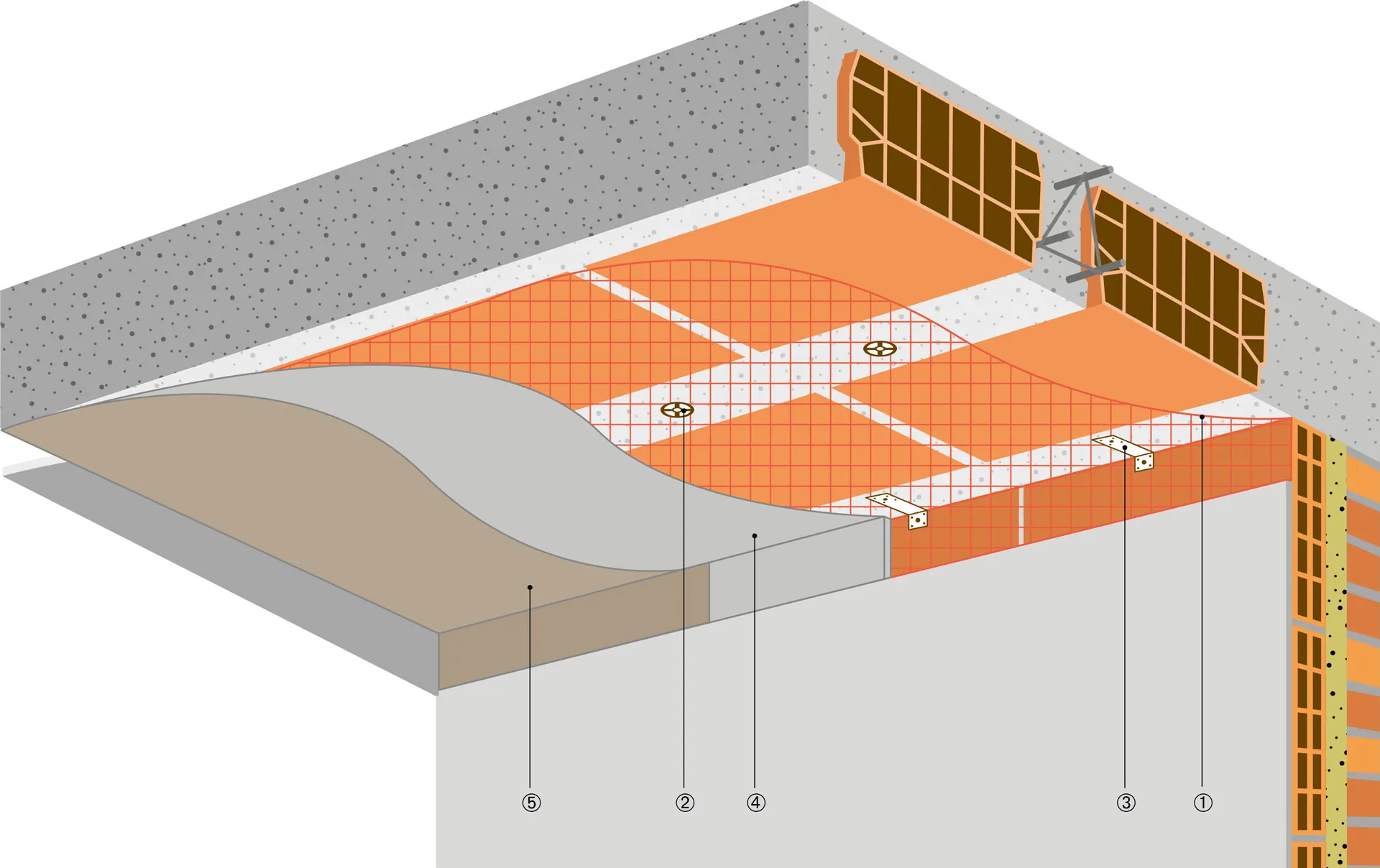

Application stratigraphy

- ARMAGLASS STRUCTURA 250

- FLANGIA CON VITE

- SQUADRETTA CON TASSELLI

- UNISAN

- SANASTOF