APPLICATION PROCEDURES

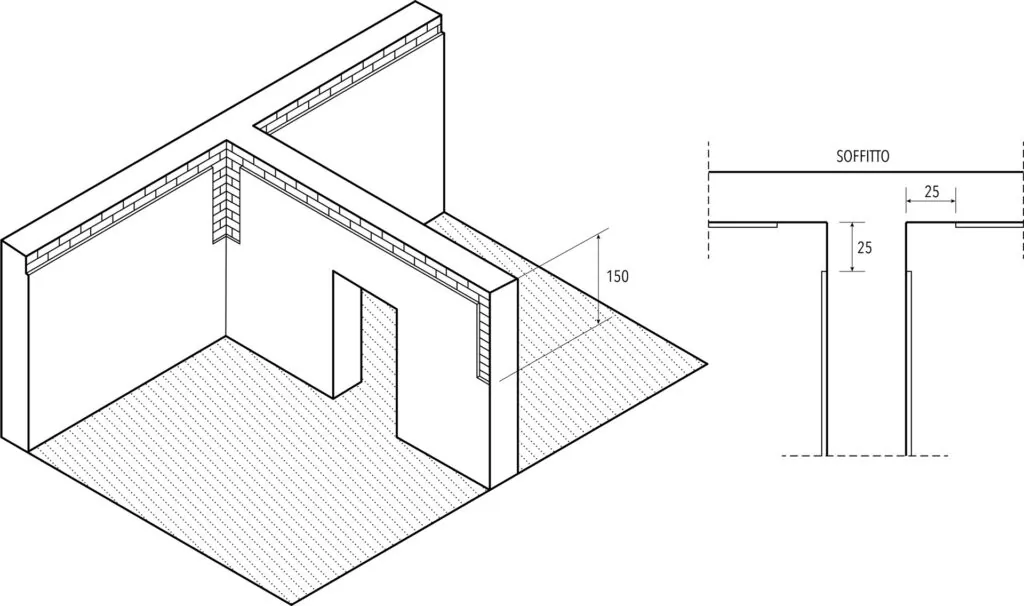

- Remove the existing plaster between the masonry and the beam (or the floor) for a width of 50 cm (25 + 25 cm).

- Dust the carving surfaces and wash them with low pressure water.

- If through connections are foreseen, proceed with the drilling of the masonry for the entire thickness in the recessed section between the infill and the beam, according to a center distance of the holes not exceeding 50 cm and the temporary occlusion, with a special removable marker, to allow its identification and prevent the mortar to be subsequently applied from penetrating it.

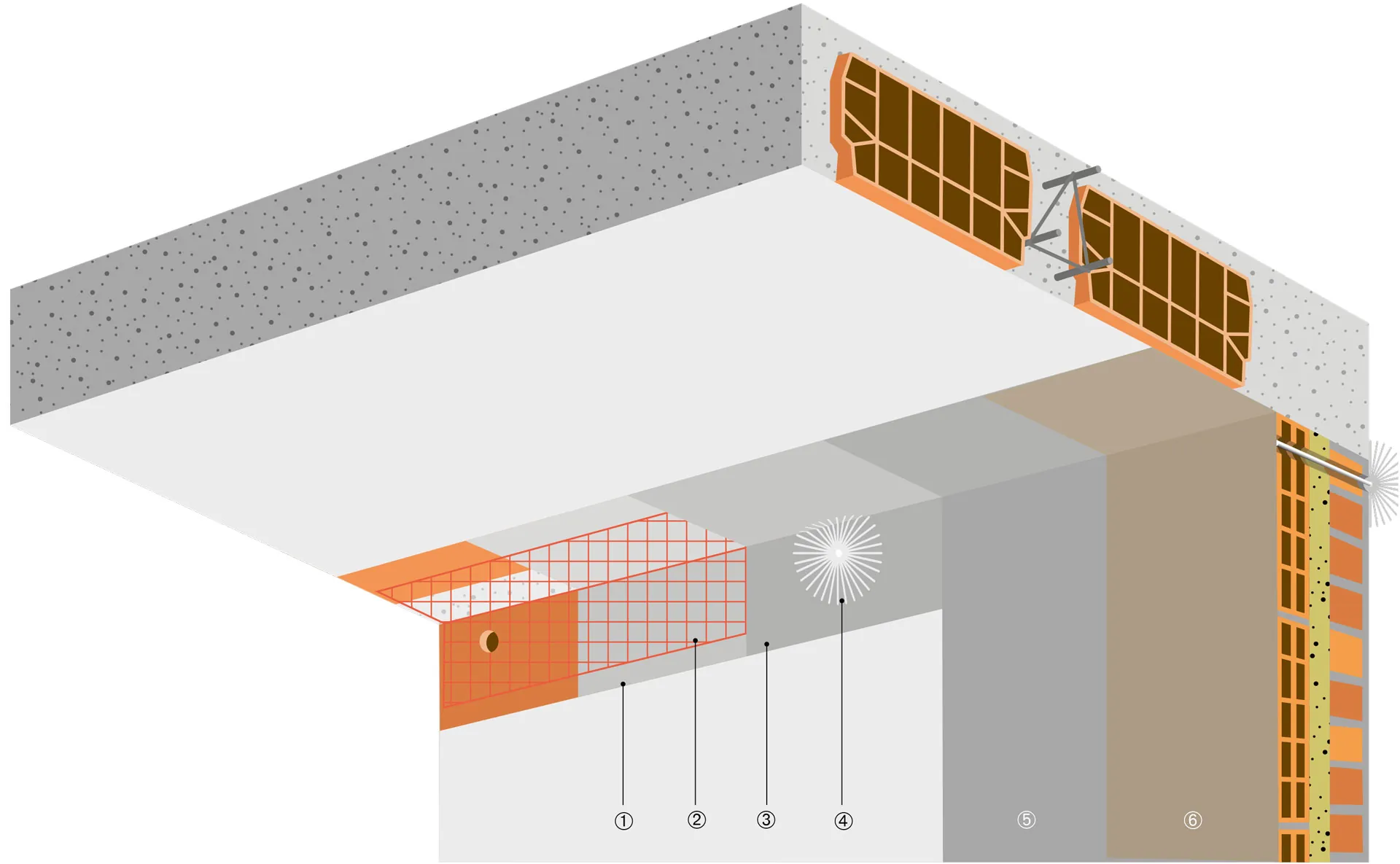

- On a substrate, saturated with water with a dry surface, application by trowel or spray of a first uniform layer of UNISAN (1) composite mortar, fiber-reinforced with double type of READYMESH fibers (glass and polypropylene), dehumidifying, very high breathability, class R (restoration according to UNI EN 998/1), based on hydraulic binders with a low content of soluble salts, with mechanical resistance in class R2 (according to UNI EN 1504/3), reaction to fire class A1 (EN 13501-1), permeability to water vapor 11 μ (UNI EN 1015-19), compressive strength after 28 days> 20 N/mm² (UNI EN 12190), flexural strength after 28 days> 5MPa (UNI EN 12190) elastic modulus 11 GPa (EN 13412), maximum particle size of the aggregate 1.5 mm.

- On the still “fresh” mortar layer, place the ARMAGLASS STRUCTURA bi-directional glass fiber reinforcement mesh (2), exerting light pressure with a flat metal trowel so that it adheres perfectly to the applied mortar

(2) Use the ARMAGLASS STRUCTURA 250 mesh, or alternatively ARMAGLASS STRUCTURA 115 according to the design indications (usually ARMAGLASS STRUCTURA 250 is used in the perimeter cladding and ARMAGLASS STRUCTURA 115 in the internal partition walls).

- Wet application of a second layer of UNISAN mortar (1) to completely cover the net; thickness of the mortar from 1 to 2 cm approximately. Consumption of 15 kg/m²/cm of thickness.

- If connection systems are provided, leave a 20 × 20 cm net surface visible, centered with respect to each of the holes previously made, and insert the special connection systems with rigid central core and staple terminations in glass fiber ARMAGLASS CONNECTOR TWIN. This special connector is available in different lengths of the rigid central part (20-30-40-50-60 cm) to be chosen according to the thickness of the masonry; the loose part in the bow, common to all available lengths, is 20 cm on each side.

- Fill the holes and grout the connectors with GROUT CABLE pourable grout or, alternatively, with SYNTECH FIX EP epoxy resin for anchors.

- Spread the loose fibers of the terminal part of the connector radially, connect them by intertwining them with the meshes of the net.

- Incorporate everything with UNISAN fiber-reinforced composite mortar (1).

- Two-coat smooting performed with SANASTOF premixed mineral composition, based on natural hydraulic lime NHL 3.5, microsilica with pozzolanic activity, selected aggregates, high tenacity microfibers, light heat-insulating aggregates with low modulus of elasticity; consumption of about 3 kg/m² for two applied coats and a total thickness of 2-3 mm.

- Finish the surgery with a highly breathable colored finish using product from the SANAXIL or PROTECH SIL line

* as an alternative to UNISAN mortar, the super-adhesive RASOCOAT mortar can be used, based on hydraulic binders, water-dispersible resins, silico/calcareous aggregates and specific agents. Main technical characteristics of RASOCOAT mortar: Adhesion bond (UNI EN 1015-12): > 1.5 N/mm²_ Density: 1.90 kg/l _ Compressive strength after 28 days (UNI EN 1015-11): > 20 N/mm² _ Flexural strength after 28 days (UNI EN 1015-11): > 6 MPa

Application stratigraphy

- UNISAN (1° layer)

- ARMAGLASS STRUCTURA 250/115

- UNISAN (2° layer)

- ARMAGLASS CONNECTOR TWIN

- UNISAN (3° layer)

- SANASTOF